Newsletter - Volume 1 Issue 2

In this issue:

In this issue:

- Touchless Technology for Vending and Kiosks

- How To Prevent Harmonic Distortion

- Cooling Sheet Metal Machine

- SlimLine Series of Air Conditioners

Featured video: See touchless vending.

To view newsletter in your browser click here.

Touchless Technology for Vending and Kiosks

|

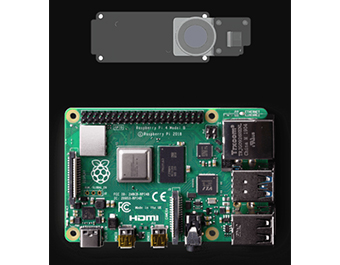

Winner of a 2021 CES Innovation Award, Vtouch created a "virtual touch panel." This product combines a 3D digital camera with a control board and AI software to make the 3-dimensional space in front of the camera a virtual control panel that does not require any contact with an actual panel. |

|

How To Prevent Harmonic Distortion

Variable frequency drives (sometime referred to as variable speed drives) are often installed in enclosures as they are used to control the speed of compressors, fans and pumps. They provide a control mechanism and help with achieving better energy efficiency.

The problem is they also can cause harmonic distortion that can adversely affect any powered device in the cabinet. According to sources, "harmonic distortion can also be caused by fluorescent lighting ballasts, uninterruptible power supplies, computers and office equipment."2

Harmonics in variable frequency drives are created when the device only draws current a small portion of the time producing a secondary wave at higher frequency than the line alternating current (A/C). Some of these harmonic waves can be cancelled out if they are multiples of two or three of the line frequency. Others, if they are carrying enough current, can cause distortion.

So what problems can harmonics cause? According to a variable frequency drive manufacturers association2, "Higher order harmonics can interfere with sensitive electronics and communications systems, while lower order harmonics can cause overheating of motors, transformers, and conductors."

So can this problem be easily solved and how is it solved? The answer is many harmonic distortion problems can be solved by selecting power supplies that incorporate components to limit total harmonic distortion (THD) to less than 5%. Additionally, AC line reactors and DC chokes can be used. Properly used, these components will make the current drawn from the power source conform more to a sinusoidal pattern.

There is a good article here3 from Nidec Motor Corporation that describes this issue in some detail including schematic drawings showing how an LC filter can be implemented using inductive coils and capacitors to filter out undesirable distortion.

Sources:

2. http://www.vfds.org/vfd-harmonics-and-mitigation-726582.html

3. https://acim.nidec.com/drives/control-techniques/-/media/controltechniques/documents/enus/ whp_harmonicmitigation.pdf

Cooling Sheet Metal Machine

|

Sheet metal punching and sheering machines use hydraulic power to produce a variety of metal structures, ventilation ductwork and other metal products. |

|

| Cooling Sheet Metal Machine |

SlimLine Series of Air Conditioners

|

If you have a question about enclosure cooling for your specific application, Seifert Systems' technical staff would be glad to speak with you. Email us at info.us@seifertsystems.com or call 401-294-6960 .

Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor